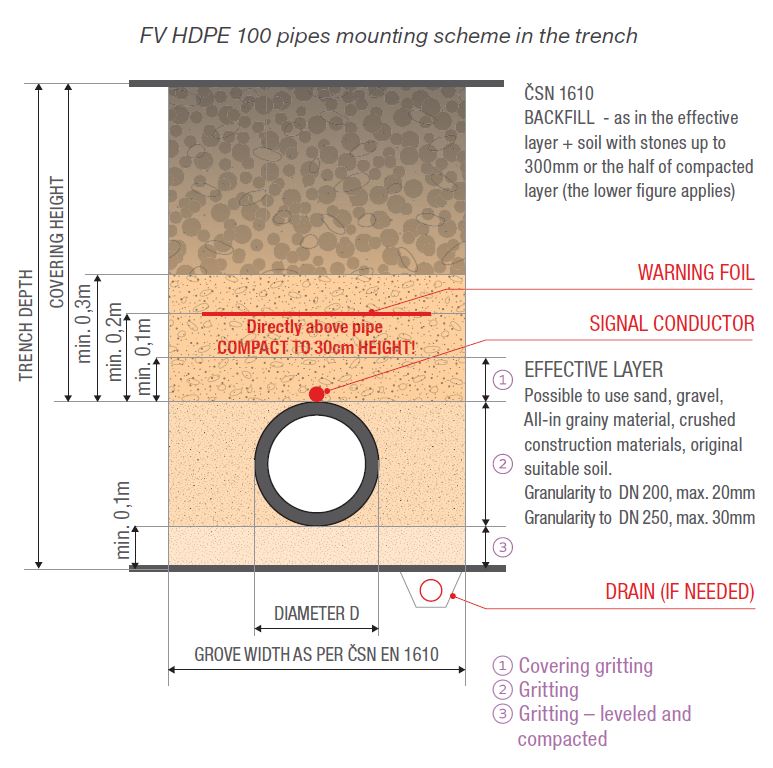

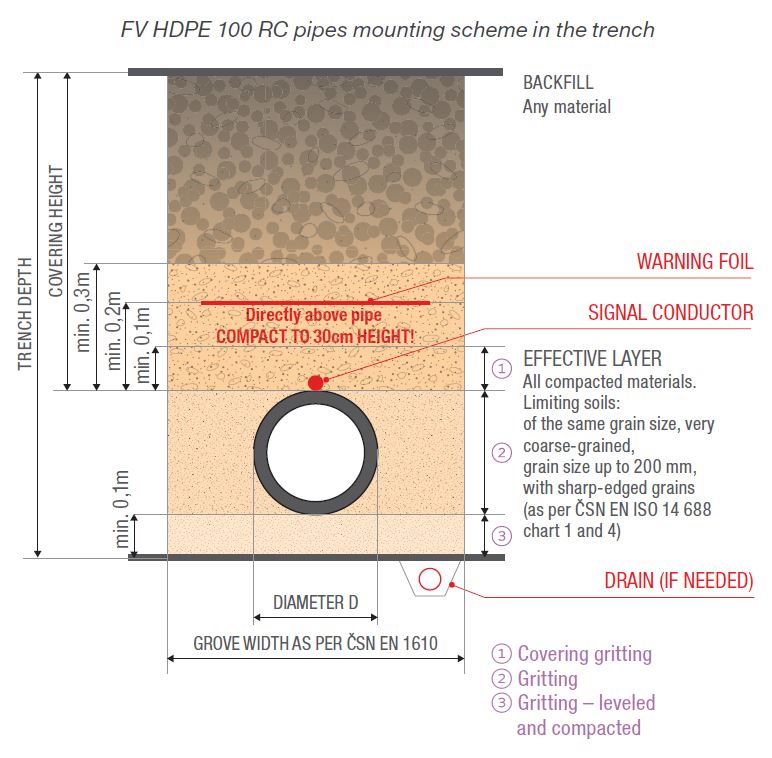

The soil under the pipe and to 15 cm above pipe upper margin is considered effective (see schematic sectional views of mounting).Embankment and compaction is made layer after layer, always on pipe’s both sides. The pipes of 110 mm diameter or higher are compacted manually or using soft-compacting machinery. Compaction is not used directly above the pipe to the height of 30 cm. When compacting, the pipes cannot be moved vertically or horizontally. PE 100RC pipes can be used for so called “non-sand layout” for most common trenches and covered by dig material to 50 % of aggregate additives of the size to 250 mm.

The PE100 pipes are placed into the trench on sand or sandy gravel base of minimal thickness of L = 10 cm. The soil does not need to be compacted, although it cannot be too loosen. The effective layer gritting is made by sand or soil without sharp-edged parts for the HDPE 100 piping and pipe fittings. The pipes cannot be placed on the frozen soil. The entire pipes have to lay on the terrain, without point contact with the rock - assembly holes are created in case of the mechanical pipe fittings or the electrofusion pipe fittings. Mounting angle should be larger than 90°. The new sand or sandy gravel base has to be created for the pipes (excluding

RC pipes) in rock or stone bedrock after removing approximately 15 cm layer. For pipe fittings gritting, the sand is used for each type of piping if not stated

differently. The gritting should exceed the pipe fitting by 20 cm minimum on each side.

The pipes CANNOT be placed directly on concrete or other hard surfaces. If the concrete sheets are used in soils of low-bearing capacity, the 15 cm sand or sandy gravel base has to be created.

PIPING GRITTING AND BACKFILL

The soil corresponding with the specification for the effective layer and given type of piping is used. Hollows cannot emerge in the pipe surroundings, thus, materials that can change their volume or consistency cannot be used for backfill. Water pipes cannot go through the soil contaminated by organic material. This soil cannot be used for gritting. The unsuitable soil has to be replaced with suitable soil.

A warning foil marking the pipes it recommended as per CSN 73 6006 (8/2003). The foil should be placed above the pipe top in 20 cm minimum. The material and compaction method corresponding to the use of given area is used for the pipes